Understanding Metric DIN Fittings: A Business Essential

The realm of industrial hardware is vast and often overwhelming, especially when it comes to fittings for sale that ensure stability and efficiency in various applications. Among these, metric DIN fittings have emerged as a crucial component that businesses across numerous sectors cannot afford to overlook. In this article, we delve deeply into the details surrounding metric DIN fittings, their significance in modern manufacturing and construction, and how they can propel your operations to new heights.

What Are Metric DIN Fittings?

DIN stands for 'Deutsches Institut für Normung' (German Institute for Standardization), which sets globally recognized standards for industrial components. The metric DIN fittings are specifically designed to meet stringent criteria, ensuring compatibility and reliability across various systems.

These fittings encompass a wide range of products used to connect pipes, hoses, and other equipment in hydraulic and pneumatic systems. They are meticulously engineered to provide a leak-proof connection that can withstand high-pressure environments.

Why Choose Metric DIN Fittings?

Choosing metric DIN fittings offers numerous advantages that contribute to the efficiency and safety of your operations:

- Standardization: Being aligned with international standards, these fittings ensure compatibility across global markets.

- Quality Assurance: Sourced from reputable manufacturers who adhere to strict quality control measures, providing long-lasting durability.

- Versatility: Available in various sizes and configurations, suitable for a wide range of applications.

- Improved Safety: Designed to minimize leakage and withstand extreme pressures, increasing safety in operational environments.

Applications of Metric DIN Fittings

Metric DIN fittings serve a myriad of applications. Some key sectors include:

1. Hydraulic Systems

In hydraulic applications, the integrity of connections is paramount. Metric DIN fittings provide the robust links necessary for transferring high-pressure fluids, ensuring operational efficiency and safety.

2. Pneumatic Systems

Pneumatic systems benefit from the lightweight design and reliable performance of DIN fittings, allowing for effective air supply and control.

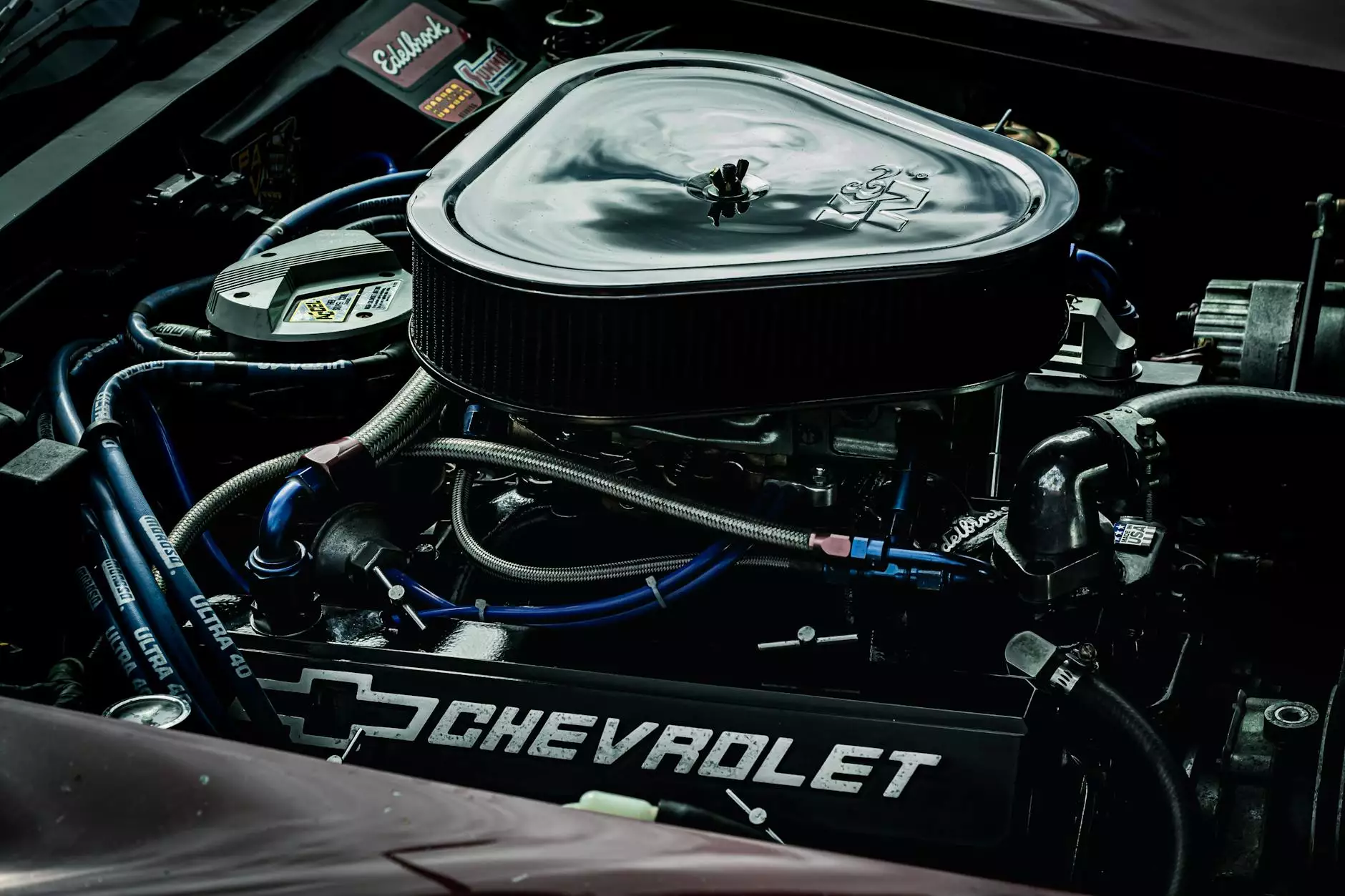

3. Automotive Industry

In the automotive sector, these fittings are essential for functions ranging from fuel delivery to braking systems, where reliability is non-negotiable.

4. Manufacturing and Construction

The industrial sector makes extensive use of metric DIN fittings for assembling machinery and equipment, where they ensure seamless operation and longevity.

Key Specifications of Metric DIN Fittings

To fully grasp the value of metric DIN fittings, it is vital to understand their specifications:

- Material: Typically made from steel, stainless steel, brass, or plastic, depending on the application needs.

- Thread Types: Common thread types include metric threads, BSP threads, and NPT threads, ensuring a wide compatibility.

- Pressure Ratings: Ranging from low to ultra-high pressure, tailored to fit various hydraulic and pneumatic requirements.

- Temperature Resistance: Various coatings or materials are used to withstand high temperatures, suitable for specific industry conditions.

Choosing the Right Metric DIN Fittings

Selecting the right metric DIN fittings for your business requires careful consideration of several factors:

1. Application Requirements

Identify the environment in which the fittings will be used. Factors like pressure, temperature, and the medium being transported will significantly influence your selection.

2. Compatibility

Ensure that the fittings you choose are compatible with existing setups. This includes matching thread types and sizes with your current equipment.

3. Quality Standards

Always opt for fittings that adhere to international quality standards. Check certifications and the reputation of suppliers like fitsch.cn.

The Future of Metric DIN Fittings

As industries evolve and embrace new technologies, the demand for innovative fittings continues to rise. Expect advancements that integrate smart technologies, enabling real-time monitoring and control of fitting performance. The future holds tremendous potential for those willing to adapt and invest in high-quality fittings.

Where to Buy Metric DIN Fittings

For top-quality metric DIN fittings, consider purchasing from reputable suppliers such as fitsch.cn. They offer a comprehensive selection of fittings tailored to meet various industry needs, ensuring you find the perfect match for your operations.

Why Choose Fitsch?

- Extensive Selection: A diverse inventory of metric DIN fittings and other components.

- Expert Guidance: Knowledgeable staff available to help you select the right fittings for your specific applications.

- Competitive Pricing: Reasonably priced products that do not compromise on quality.

- Fast Shipping: Efficient delivery services to ensure your operations remain uninterrupted.

Conclusion

In conclusion, metric DIN fittings are indispensable in a variety of industries, offering unmatched reliability and performance. Investing in high-quality fittings not only enhances the efficiency of your operations but also contributes to safety and longevity. As you consider your options, remember that suppliers like fitsch.cn can provide you with the necessary products and support to ensure your business thrives.